Overview

Full-automatic ion exchanger is a brand new environmental-friendly, economical and safe soft water treatment system, developed based on successful engineering practical experience, in accordance with national and industrial standards.

Resin tank of the full-automatic ion exchanger is made from top-grade glass steel, stainless steel, carbon steel-lined plastics, and other antiseptic materials. With superior quality and stable and reliable performance, the equipment realizes full automatic operation, requires no special attendance, and has high cost performance and satisfactory effect.

This system can be applied to boilers, air conditioning, and refrigeration systems in petrochemical industry, light and textile industry, food sanitation, and hotels, etc.

Working Principle

Water hardness is mainly contributed by calcium (Ca2+) and magnesium (Mg2+) ions. When hard raw water flows through the resin layer of an ion exchanger, calcium and magnesium ions therein will be absorbed by the resin; and meanwhile, sodium ions will be released. In this way, hardness ions are removed and the water flowing out of the exchanger is soft water. When the resin is saturated with calcium and magnesium ions, outlet water hardness will increase. In this circumstance, water softener will start to regenerate the resin automatically according to the preset program. High-concentration sodium chloride solution (salt solution) will pass through the resin, so that the ineffective resin will be restored to the sodium form.

Equipment Characteristics

ĄĄ1. High degree of automation; stable operating conditions;

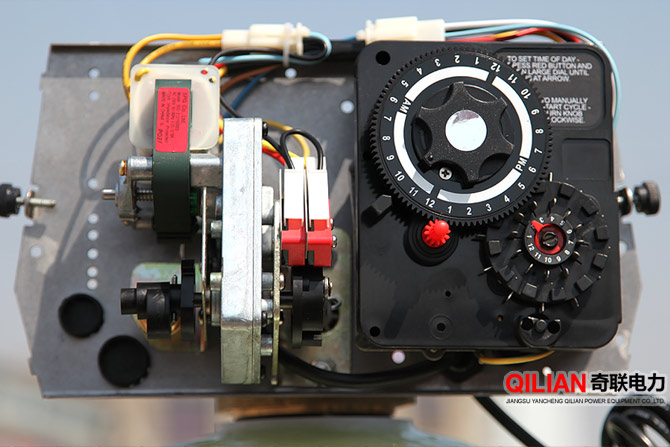

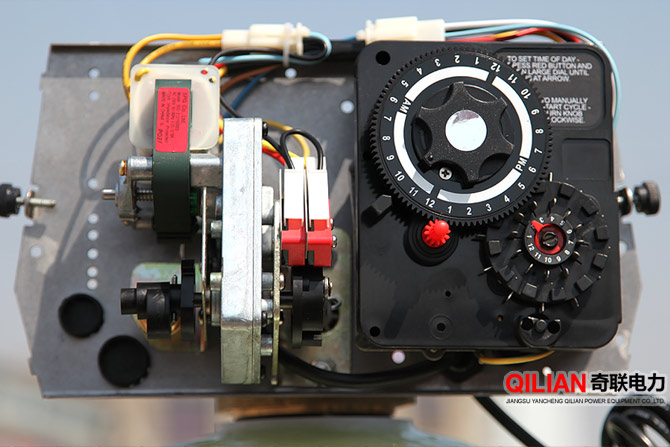

ĄĄ2. Advanced program control ensures accurate and reliable operation; manual operation is replaced; full automatic operation of water treatment is realized.

ĄĄ3. High efficiency, low power consumption, and low running cost; the reasonable design of water softener brings into full play the absorbing capacity of resin. Jet self-suction pump is used as a substitute for salt pump, which reduces energy consumption.

ĄĄ4. The equipment is compact in structure, requires small floor space and low investment in basic construction, and is easy to install, debug and operate; with steady performance.

Water Intake Requirements

Residual chlorine< 0.1ppm Turbidity< 2 FeĄī03ppm

Mn < 0.3ppm Total salt content < 500 ppm

Main Points of Construction and Installation

ĄĄĄĄ1). A support shall be provided for the pipeline to prevent stress on the control valve.

ĄĄĄĄ2). When the water inlet pipe of the softener is connected with the domestic water pipeline, a backflow preventer shall be installed on the inlet pipe.

ĄĄĄĄ3). When the inlet water pressure is lower than 0.15MPa, pressure application measures shall be taken.

ĄĄĄĄ4). The drain pipe length shall be less than 6m, with no valves thereon; the outlet shall not be higher than the valve body; the drain pipe shall be open ended, for fear of syphonage.

ĄĄĄĄ5). There shall be a 220V power supply at the operation site, apart from the softener with a water power multiple unit valve.

ĄĄĄĄ6). Iodized salt cannot be used; calcium-added salt shall be used as regenerant.

Technical Parameters

1. Treatment Effect

Outlet water hardness:  0.03mmol/l 0.03mmol/l

2. Water Intake Requirements

Raw water hardness: in conformity with Ą°Specification for Automatic Sodium Ion Exchanger (GB/T 18300-2001)Ąą

Inlet water turbidity: Ģž10mg/L;

Inlet free chlorine:  0.3mg/L; 0.3mg/L;

Inlet suspended substance: Ģž5mg/L;

Inlet iron content: Ģž0.3mg/L;

Inlet water pressure: 0.2-0.6 MPa;

Inlet water temperature: 5-45

3. Operating Parameters

Resin Model: 001 7 strong acid cation exchange resin; 7 strong acid cation exchange resin;

Working power supply: 220VĄĀ22V/50HZ:

Regeneration mode and control: cocurrent flow dynamic regeneration; time control, flow control, and detection control

Connection type: thread or ABS flange

|

0.03mmol/l

0.03mmol/l

7 strong acid cation exchange resin;

7 strong acid cation exchange resin;